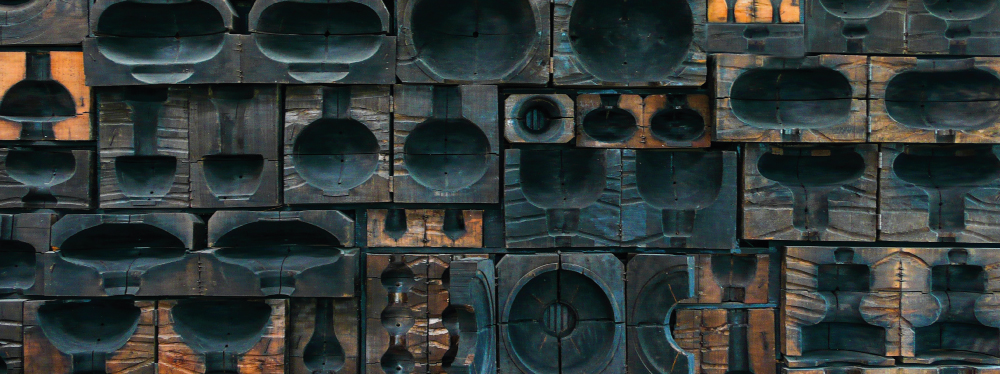

ShellMould

Um novo conceito de molde integrador para maximizar a produção de embalagens de vidro à afirmação no mercado internacional

Desafio

O principal desafio que se coloca atualmente na indústria vidreira é solucionar a heterogeneidade de temperaturas que se verificam na superfície moldante dos moldes. A utilização de materiais diferentes para a construção do maciço dos moldes e a aplicação de novos materiais como revestimentos na sua superfície moldante alteraram significativamente as condições de arrefecimento no interior do molde. Para além das variações de propriedades mecânicas que podem ocorrer devido a diferentes velocidades de arrefecimento (razão pela qual a temperatura na superfície não é homogénea), o problema agrava-se, já que, durante o processo de moldação sopro, as diferentes temperaturas vão levar a valores de espessura diferente no produto que está a ser enformado. O controlo eficiente do arrefecimento do molde é, neste momento, a ação mais aliciante a otimizar pelas empresas fabricantes de moldes para vidro. Com efeito, sabendo que os problemas de desgaste prematuro e de lubrificação estão resolvidos, se o sistema de arrefecimento permitisse obter uma maximização de extração de calor associada a uma homogeneização de temperaturas na superfície moldante (ou, melhor ainda, um controlo eficaz da temperatura em todas as zonas do molde), facilmente se poderia compensar os custos mais elevados das soluções de Engenharia de Superfícies através de:

(i) aumentos de produtividade;

(ii) diminuição da matéria prima do vidro proporcionada por uma distribuição de espessuras de acordo com as necessidades;

(iii) produtos finais mais leves e com melhores propriedades e, (iv) melhoria energética de todo o processo produtivo.

Solução / Objetivo Principal

Contribuir para a fabricação de moldes de embalagens de vidro que permitam eliminar os problemas inerentes à fissuração, oxidação, corrosão, adesão do vidro à superfície moldante, distribuição heterogénea de espessuras no produto final, tudo isto sem haver impacto negativo nos custos de produção, na produtividade, no consumo energético, no consumo de matérias-primas dispendiosas, nas condições de trabalho e no meio ambiente. Deste modo, pretende-se desenvolver soluções de engenharia para componentes moldantes da indústria vidreira, utilizando um conceito que permita simultaneamente integrar os desenvolvimentos já alcançados, no que respeita os materiais de base e as soluções de Engenharia de Superfícies, e criar condições para diminuir os custos envolvidos com a aquisição desse material e, ao mesmo tempo, otimizar um sistema de arrefecimento eficaz do ponto de vista de extração de calor e de controlo da temperatura na superfície moldante.

Objetivos, Atividades e Resultados esperados / atingidos

Resultados esperados:

a) Desenvolver um molde multicomponente (maciço + casca) que permita na zona de interface incorporar canais de arrefecimentos distribuídos de forma otimizada e na superfície da casca revestimentos com baixo atrito, de modo a em conjunto permitir o fabrico de embalagens sem defeitos com aumentos de cadência de produção.

b) Desenvolver um modelo de simulação do comportamento térmico de um molde maciço/casca que em função das condições de produção deverá permitir desenhar canais de arrefecimento que promovam uma extração de calor eficiente e homogénea e que permita determinar a distribuição de temperaturas na superfície moldante em função das condições de arrefecimento e de produção de embalagens de vidro.

c) Diminuir a quantidade do material que possui elevada condutividade térmica, usualmente bastante dispendioso e aplicar revestimentos já desenvolvidos no âmbito de outros projetos para melhorar as propriedades tribológicas, térmicas, lubrificantes e mecânicas da superfície da casca.

d) Otimização das estratégias de maquinação, sinterização e fundição, visando a redução das fases de fabrico, aumento da qualidade e redução de custos. No final, os protótipos produzidos deverão garantir uma diminuição do tempo de ciclo em 10%, uma diminuição de utilização de matéria-prima em 20% (mesmo objetivo para a massa do produto final), um decréscimo do consumo de energia em 20% e uma diminuição da taxa de rejeição em 50%.

Resultados atingidos:

a) Fabrico de um novo molde bi-componente funcional do tipo casca + núcleo moldante;

b) Desenvolvimento de um modelo numérico adaptável à geometria e à constituição do novo sistema de arrefecimento, que simula os fluxos térmicos e a distribuição de temperaturas na superfície moldante;

c) Desenvovlimento e aplicaçao de um revestimento fino com propriedades autolubrificantes que reduziu o desgaste provocado pelo vidro fundido.

Assim, como resultado principal, destaca-se a eficiência do novo molde em ambiente industrial, que do ponto de vista de arrefecimento, em comparação com o molde tradicional, revelou ter um decréscimo de temperatura de 30ºC na superfície do molde durante a produção de embalagens de vidro, estimando-se um impacto significativo na redução de custos energéticos a médio prazo. Deste modo, é possível antever ganhos importantes de produtividade e competitividade nacional e internacional das empresas envolvidas.

Do ponto de vista de exploração dos resultados, destacam-se a publicação de 3 artigos científicos (um já submetido e dois em fase de conclusão) e a submissão de um pedido de patente provisória relativo ao inovador sistema de arrefecimento, desenvolvido para o novo conceito de molde.

Referência do projeto

POCI-01-0247-FEDER-039913Financiamento

Região de Intervenção

Centro (100%)Investimento Total

827.639,45Investimento do IPN

183.223,37Elegível Total

825.159,45Elegível do IPN

183.223,37Apoio Financeiro da UE - Total

545.186,12Apoio Financeiro da UE – IPN

137.417,53Duração

36 MesesData de Início

2019-10-01Data de Fim

2022-12-31Data de Aprovação

2019-08-27Consórcio

Intermolde - Moldes Vidreiros Internacionais, Lda;BA Glass Portugal, S.A.;

Instituto Pedro Nunes - Associação Para a Inovação e Desenvolvimento em Ciência e Tecnologia;

Universidade de Coimbra.

Palavras-chave

Revestimentos finos;Engenharia de superfícies;

Indústria vidreira;

Moldes;

Ciclos térmicos;

Controlo de temperatura;

Embalagens de vidro;

Simulação numérica;

Arrefecimento.